Message from Stefan Kipp EMD of AlBihouth

Welcome to our October newsletter. We were pleased to receive to site and install the main feedwater tank this month. This tank holds the process water for the water-steam cycle for both line 1 and line 2 boilers. As we close October we now have 1,400 personnel working on site, with day and night shift crews operating 24/7. The workforce will continue to grow as we enter the peak construction phase, that will culminate in March 2026. EPCs latest subcontractor Jurong Engineering have now joined the workforce, and they will be responsible for the erection of the air-cooled condenser system. We were pleased to welcome guests from the Marubeni HSE directorate to site this month. They were very interested to see our HSE School of Risk facility that we use to train our staff. Following on from their visit they have adopted this idea into their own assets here in the middle east. We also hosted KVI corporate team members from the USA and Switzerland, who were interested to see how our waste to energy project is progressing.

Project Summary to Date

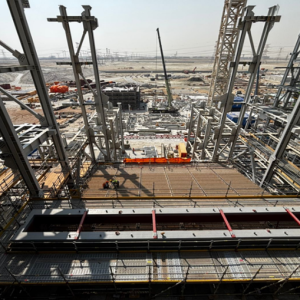

The sub-surface turbine oil run off pit has now been waterproofed and fully closed, which has allowed works to begin on the base stubs and supports of the top-side air cooled condenser. The ACC structures are called streets, and each of the two lines has its own ACC street, where steam that has passed through the turbine is cooled back to liquid state. Erection of process equipment in line 2 has intensified this month, with the top two sections of the feed hopper now fully installed, and sections of the primary air pre-heater lifted into position. Membrane walls on the sides and inner sections of the combustion chamber in line 2 continue to be lifted into position. Due to the size of the boilers the inside of the combustion chambers are sub-divided with intermediate walls. This maximizes the wet steam production capability, prior to an additional steam heating process in the superheater elements, that will bring the steam temperature to 417 degrees C at 66 bara.

Access to the full length of the feed hopper deck at 23m level is now possible from the administration building, which is now at fifth floor level, and via a scaffolding staircase on the eastside crane maintenance bay enclosure. Erection of the turbine annex steel structure continues, and we expect the turbine to be delivered to site early January 2026. The turbine and the generator are both supplied by Siemens, who will oversee the installation and commissioning of the units. Extensive underground service works have been ongoing throughout the month, with foundations for E-houses including electrical manholes, cable ducting pipework, and storm and sewage water pipes being installed. Fire water pipework is also being installed and pressure tested. Waste crane number 1 structures have been moved into position at the front of the waste bunker on the northside for final assembly prior to installation. Our EPC contractor is now finalizing the structural alignment of the crane rails within the bunker, after which the cranes can be lifted into position. In line 1 the bottom section of the feed hopper assembly has been fitted, and additional cube erection will resume here once structural alignment at ground level has been completed. Block work to infill the administration building walls has begun at ground floor level this month, and blockwork in the air compressor building is progressing well. EPC has begun the structural frame erection of the storage building, that is adjacent to the workshop on the eastside. On the northside works are progressing well forming the tipping bay door openings.

HSE Update

As we look ahead to plant operations, my team have been reviewing proposals for the development of our operation’s environmental management plan. This plan will describe all the regulatory requirements and controls needed to ensure environmental stewardship is fully in line with UAE law and contractual requirements. The Abu Dhabi environmental regulator EAD must approve this plan before issuing the permit to allow us to begin hot commissioning of the plant, due to start in Q3 2026. As our EPC teams increase their manpower at site, we have received a revised HSE Organization chart showing the new safety team members. We ensure that the ratio of 1 safety officer per 50 workers is maintained. This is in line with the Abu Dhabi Occupational Safety and Health System Framework (ADOSH-SF).